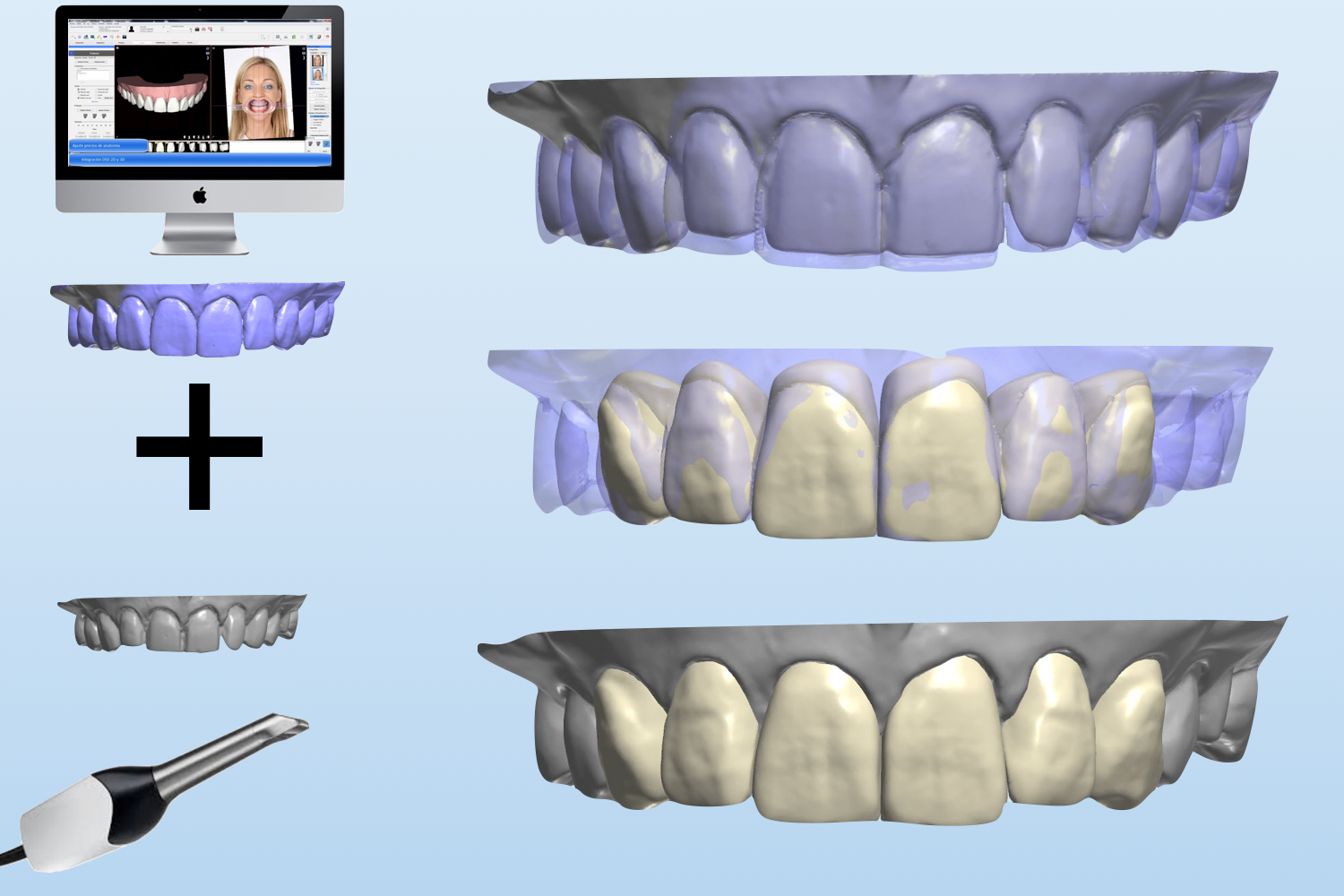

4 years ago, one of my mentors, Dr Paulo Kano, opened my eyes to a new amazing possibility for anterior restorations, the protocol that he calls the SKYN Concept. He proved that scanners were ready to copy nature, software was ready to manipulate this information (fig 1. Paulo Kano performing the SKYN Concept on Cerec software) and milling machines were ready to mill it (fig 2. Empress CAD Multi milled by Paulo Kano on a Cerec milling machine)

4 years ago, one of my mentors, Dr Paulo Kano, opened my eyes to a new amazing possibility for anterior restorations, the protocol that he calls the SKYN Concept. He proved that scanners were ready to copy nature, software was ready to manipulate this information (fig 1. Paulo Kano performing the SKYN Concept on Cerec software) and milling machines were ready to mill it (fig 2. Empress CAD Multi milled by Paulo Kano on a Cerec milling machine)

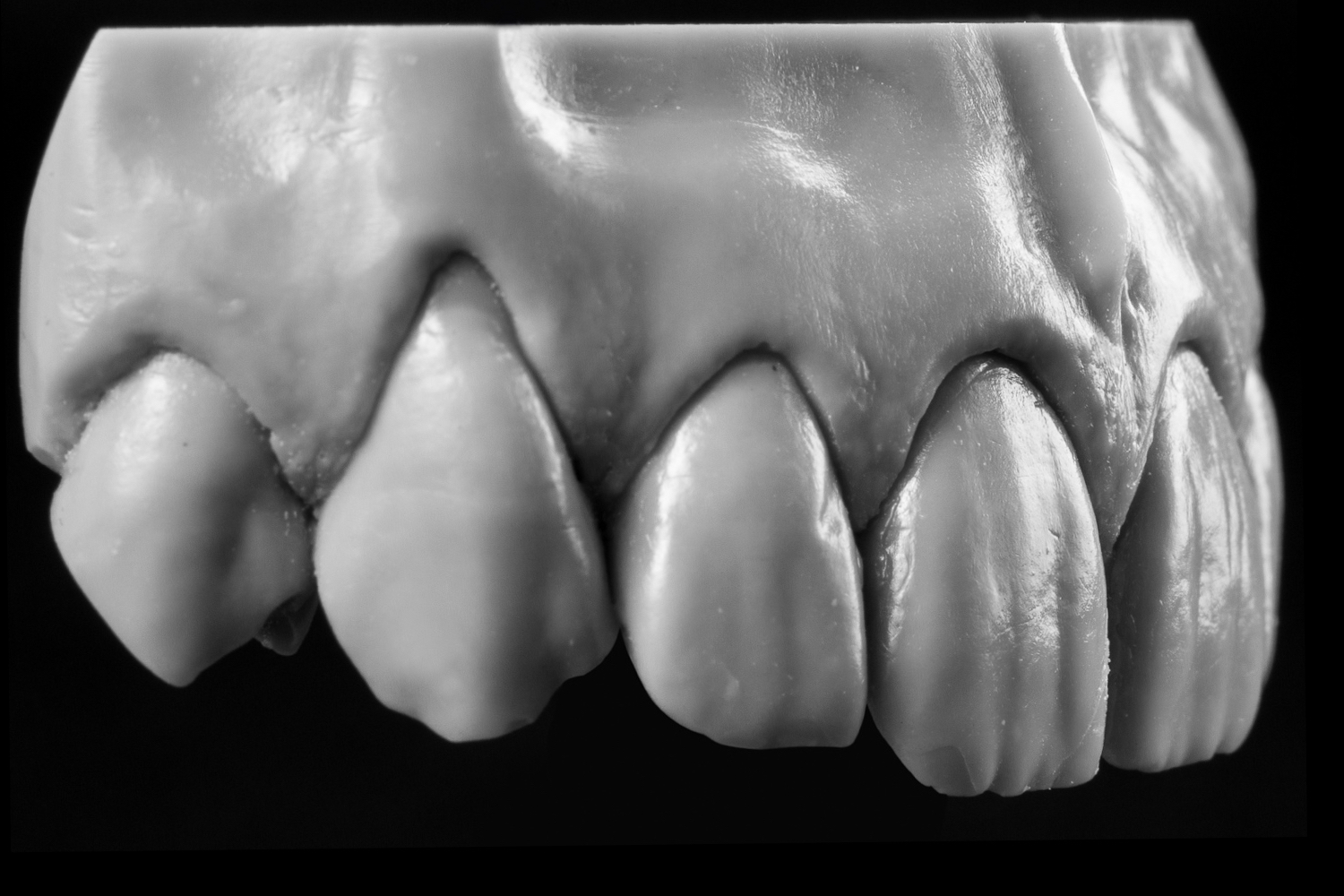

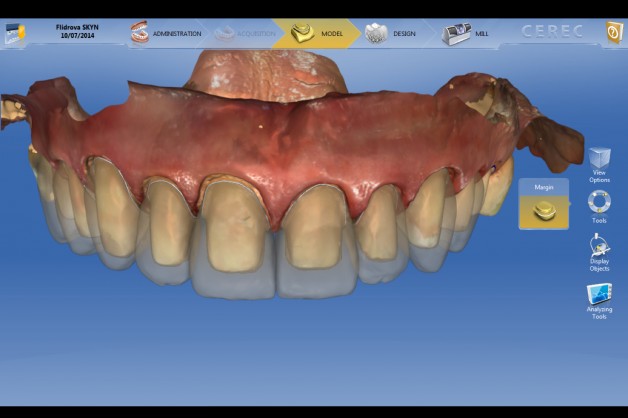

Fig 1

Fig 2

With his concept, no more handmade anatomy was needed and wax ups and ceramic layering were no longer utilized to achieve anterior beautiful restorations. The idea of using natural shapes or, as he calls, natural algorithms was a paradigm shift and confirmed that to achieve beautiful smiles, natural shapes is more important than internal characterizations (fig 3. Final outcome by Paulo Kano). It also showed that it doesn’t matter how good the ceramist is, it’s impossible to beat nature. At the same moment, companies were also doing there homework and providing us with several beautiful multi colored CAD/CAM material blocks (fig 4).

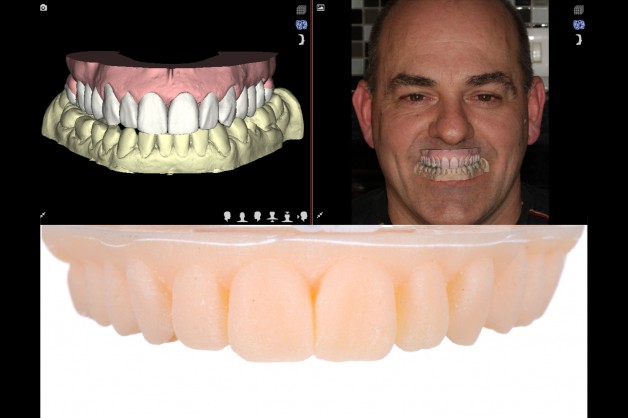

Fig 3

Fig 4

The SKYN concept was initially a half analogue and half digital procedure. Nature was copied with a silicone index done over models of beautiful natural dentition (fig 5) and than thin composite veneers were made copying this anatomy using these silicone indexes (fig 6. SKYN Concept by Paulo Kano). These composite shells where than positioned in the mouth, over the existing teeth, pre prepared or not, on the most ideal arrangement with the lips and face, like a denture setup (fig 7). This was than scanned intra orally. Tooth preparation was done and also scanned. The 2 files were than overlapped in the software and the restorations were designed copying exactly the natural shapes of the composite shells (fig 8). The milled restorations would only need some simple polishing, stain and glaze procedures and were ready to go to the mouth (fig 9. Final outcome by Paulo Kano). This process was generating beautiful anterior restorations without having to go through complex, time consuming and technique sensitive procedures as waxing, pressing or shaping and layering ceramics.

Fig 5

Fig 6

Fig 7

Fig 8

The SKYN concept was initially a half analogue and half digital procedure. Nature was copied with a silicone index done over models of beautiful natural dentition (fig 5) and than thin composite veneers were made copying this anatomy using these silicone indexes (fig 6. SKYN Concept by Paulo Kano). These composite shells where than positioned in the mouth, over the existing teeth, pre prepared or not, on the most ideal arrangement with the lips and face, like a denture setup (fig 7). This was than scanned intra orally. Tooth preparation was done and also scanned. The 2 files were than overlapped in the software and the restorations were designed copying exactly the natural shapes of the composite shells (fig 8). The milled restorations would only need some simple polishing, stain and glaze procedures and were ready to go to the mouth (fig 9. Final outcome by Paulo Kano). This process was generating beautiful anterior restorations without having to go through complex, time consuming and technique sensitive procedures as waxing, pressing or shaping and layering ceramics.

Fig 9

Fig 10

Fig 11

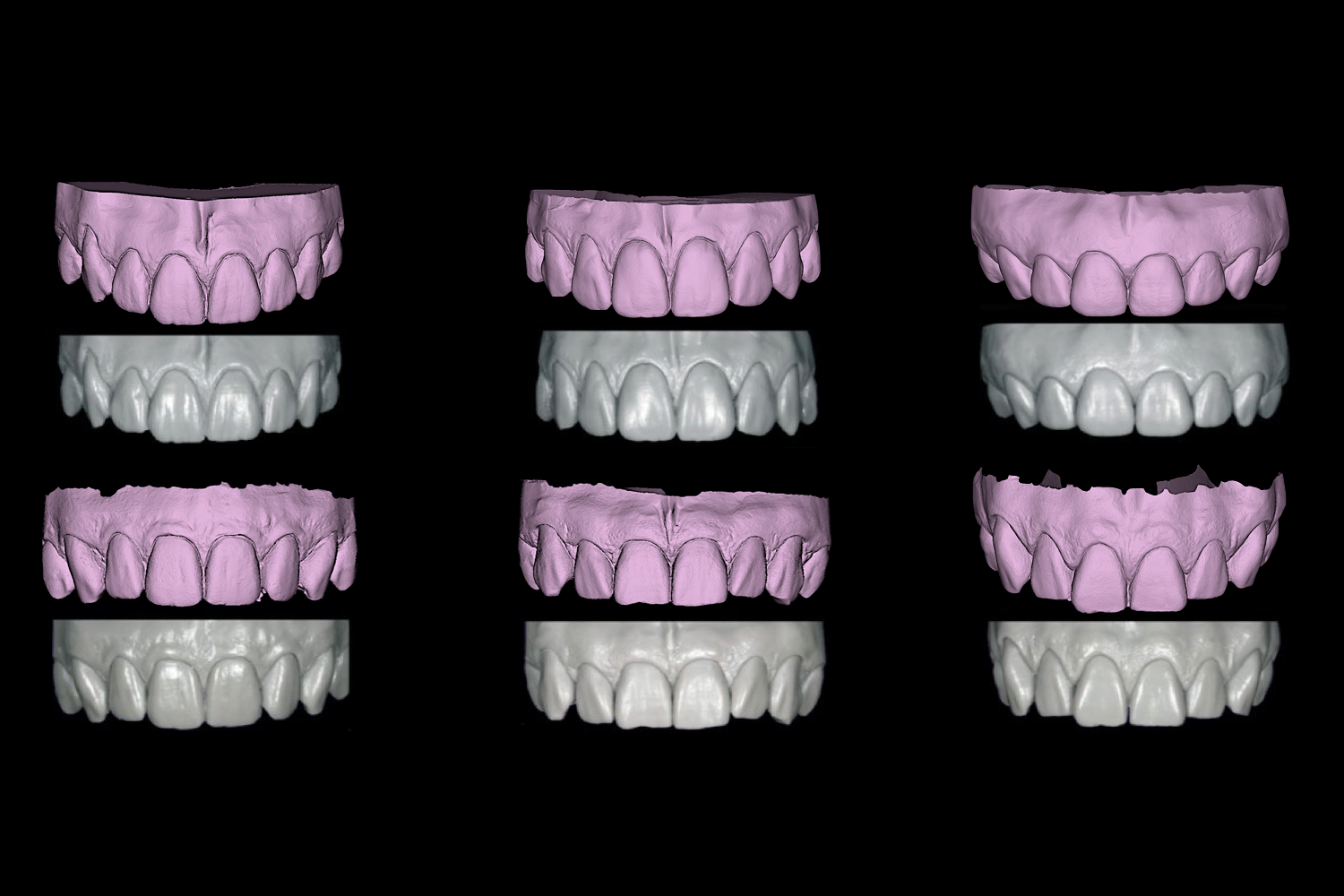

The first step to make this happen was to bring the natural tooth shape files into our NemoDSD 3D smile design and facial analyzer software. We scanned initially the models developed by Dr Jan Hajto (fig 13) and added them to the library of tooth morphology of our NemoDSD 3D software. This immediately allowed us to create ideal 3D smile design project guided by the face and lip dynamics and export these project into printing machines to develop the models. With this procedure we eliminated the need for handmade wax-ups and was able to develop mock-ups with natural algorithms.

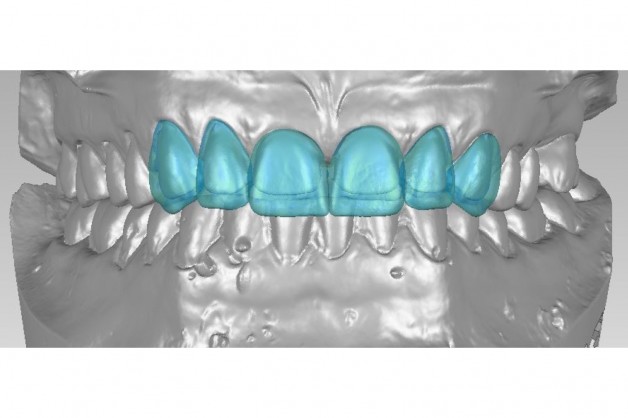

The next step, and most challenging, was to be able to export this 3D project with natural algorithms and ideal facial integration into CAD/CAM softwares and overlap it to the prep model file and than design restorations that would copy perfectly the outer shell with natural algorithms and adapt it to the finishing line of the preps without loosing the natural shapes and texture (fig 14).

Fig 13

Fig 14

2 years ago we were able to do successfully the first monolithic CAD/CAM anterior case with natural algorithms combining the 3D file from NemoDSD software and the tooth preparation file inside the Exocad software and mill it with Wieland machine. Fig 15 shows the Exocad design of the restorations based on the 3D DSD project and fig 16 shows the whole sequence of the digital workflow: Pre op situation, 2D/3D calibration and 2D smile frame, 3D digital design, mock up and final CAD/CAM monolithic ceramic restorations (Dentistry by Dr …..)

After that we started to test the process with other system, always exporting the ideal, facially driven project with natural algorithms, from NemoDSD into different CAD/CAM systems and now we have cases also done with the Zirkonzhan , Cerec In Lab and 3Shape systems.

Fig 15

Fig 16

This means that today we can make beautiful, Facially driven, monolithic CAD/CAM anterior restorations with natural algorithms using a complete digital workflow in several different systems, simplifying drastically the process of fabrication and improving aggressively the predictability of smile design projects.

It is a new and exciting restorative world ahead of us!

Written By:

Dr. Christian Coachman

Thanks for sharing Dr. Mahmoud.

It is my pleasure Dr. Saleh. Enjoy it 🙂

Valuable information

Thank you

Hi Dr. Tamim,

It is my pleasure and I am glad you like Dr. Coachman’s article.

Best regards.